Refuel Systems

Refuel is a leading manufacturer of high efficiency diesel filtration systems for commercial and industrial stored diesel applications.

Refuel is a leading manufacturer of high efficiency diesel filtration systems for commercial and industrial stored diesel applications.

Refuel employs a closed–loop filtration process to continuously filter diesel as a means of polishing, cleaning and drying the fuel. Our systems remove particulate down to 0.5μ, and emulsified and free standing water.

Refuel replaces traditional fuel management practices which deploy harsh chemical additives, annual fuel replacement or continuous operation of engines in non emergency situations to burn off fuel reserves. Refuel provides a continuous long term fuel management solution and eliminates significant gaps present in traditional, periodic fuel management practices.

The continuous nature of our closed-loop filtration system actively manages fuel quality, keeping the fuel free of particulate contamination and water ingress while eliminating diesel sludge in your tank. Refuel ensures your stored fuels integrity, 24 hours a day, 7 days a week and 365 days a year.

As a manufacturer and supplier, Refuel provides more than just a filter. We provide a complete fuel management program. We guarantee our

client’s stored fuels will meet regulatory compliance standards and engine manufacturer’s warranty requirements.

Our mission is to secure the integrity of mission critical, commercial and industrial clients fuel reserves so they maintain business

continuity during uncontrollable situations and forced emergencies.

Fuel Integrity:

It’s what’s on the inside that counts.

Like all fuels, diesel has a natural shelf life. Diesel is considered an organic fuel and like all organics it decays with age. Diesel can be reliably stored for 12 months at an ambient temperature of 20°C (65°F) and 6 to 12 months at 30°C (86°F). Molecules in the fuel lengthen and bond over time creating asphaltines (diesel sludge). Diesel sludge can clog in-line filters and damage critical engine components.

As a hygroscopic fuel (one which attracts moisture from the atmosphere) diesel often contains freestanding and emulsified water. Water can enter your critical reserves from vents on storage tanks, poorly designed storage systems, the distribution chain and interval engine testing required by local and national legislation.

Emulsified water is water which is absorbed by the fuel. This molecular bond can hold with such tenacity that traditional fuel water separators fail to remove 40% to 100% of entrained water. With the desulphurization of diesel over the last two decades and the introduction of bio-blended fuels operators need to be aware that fuel integrity can be compromised in less than 12 months and legacy fuel management programs may not be enough to protect emergency engines.

Definition of Integrity

- Adherence to moral and ethical principles; soundness of moral character; honesty.

- The state of being whole, entire, or undiminished

- A sound, unimpaired, or perfect condition

Refuel believes these are the qualities you need from the life blood of your emergency power system. You need a fuel management program that helps you meet or exceed local and National guidelines for safety and meet the continuity needs of your business.

Installing a Refuel closed-loop filtration system ensures your fuel integrity and the integrity of your entire emergency power system.

Guaranteed Performance

Fuel is a single point of failure in any emergency power system. If your fuel fails when needed the most critical systems for emergency lighting, cooling, servers and communications with quickly follow suit.

Our clients don’t just need a system to periodically manage their stored fuel; they need a partner to ensure their fuel management systems can stand the test. Refuel’s fuel management program is backed by our guarantee: Our client’s stored emergency fuel reserves will meet regulatory compliance and exceed their engine manufactures warranty guidelines. We guarantee fuel integrity 24/7/365.

How It Works

How It Works

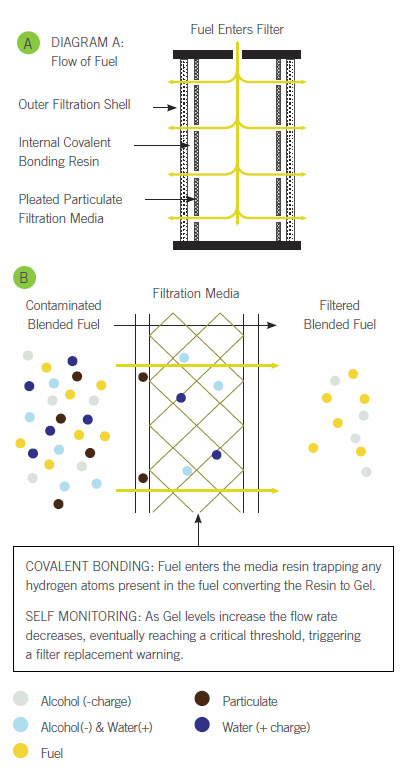

Refuel systems install as a self reliant/independent filtration systems built completely of stainless steel. With a CSA rated control panel, a patented self monitoring covalent bonding filter and filtration tank all contained in a compact NEMA rated cabinet. Refuel systems are engineered to meet requirements from 500 liters to 5 million liters and are compatible for retrofit and new installations.

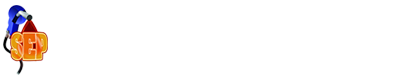

- Suction and return lines are installed into the storage tank to established a closed-loop flow

- Fuel is drawn into the filtration process and forced through the patented Integrity Series Filter

- Particulate, emulsified water and freestanding water with the filter resin are trapped inside the filter via a covalent bonding process

- The newly cleaned fuel is then returned to the storage tank where the process begins again

Advantages of the Closed-loop filtration approach

- The continuous process creates a current within the fuel tank that prevents particulate from forming and accumulating inside the tank

- The suction line is installed within one-inch of the tank floor to ensure any existing build up of microbial growth and particulate are pulled out of the tank and into the filtration process.

- The covalent bonding filter technology creates a self monitoring process that triggers a system warning as the filter reaches the end of its effective life

- Eliminating scheduled based filter replacements to reduce filter changes

- Lowers annual operating and maintenance costs

- Enhances confidence in the filters effectiveness

Click to enlarge.

LEEDS

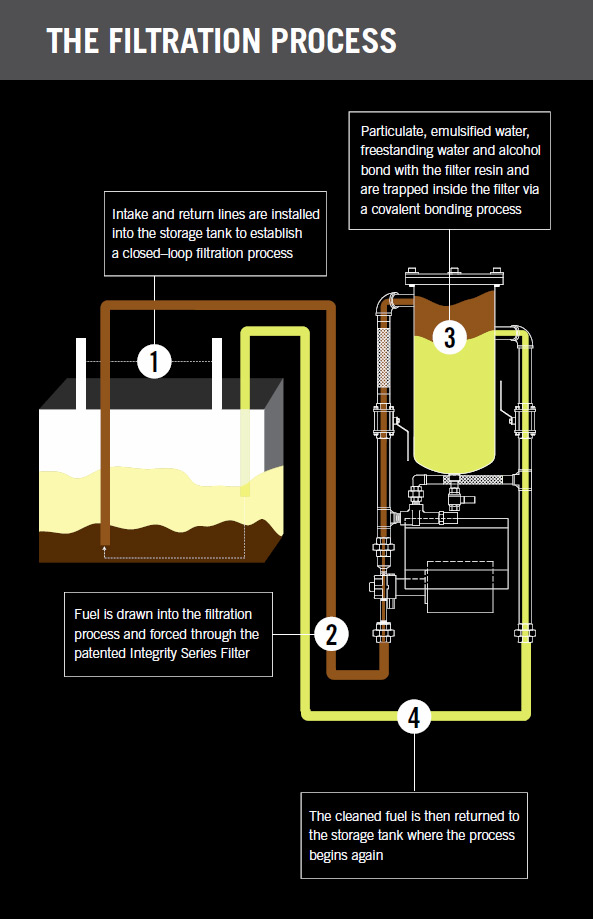

Including a high efficiency filtration system in your LEED (Leadership in Energy and Environmental Design) project can possibly qualify your project for additional points under Innovation and Best Management Practices. Refuel can help your facility go beyond any current requirements surrounding fuel conservation, minimizing fuel waste and helping to ensure optimal generator performance and emissions. If your project qualifies for LEED, interval commissioning may be a requirement.

Refuel’s Environmental Impact

- If your facility uses annual destruction and replacement to meet existing regulations installing a Refuel filtration system will drastically reduce your carbon foot print. Refuel will eliminate the need for the destruction of aging fuel reserves and the associated vehicle carbon emissions

- A proper fuel management system ensures your fuel is maintained at a pristine state enabling your engine to achieve your manufactures intended fuel economy

- Reduce the amount of fuel deliveries required when peek fuel economy is maintained

- By removing water from your fuel system you will greatly reduce the risk of internal corrosion and premature failure of tanks and lines

- Refuel can reduce increased NO 2 emissions by eliminating particulate build up that fowls’ engine components and reduce particulate not burned during the combustion process

- Help the environment by eliminating the use of harsh chemical additives that artificially maintain stored fuel and potentially increase emissions

Leadership in Energy and Environmental Design or LEED is a consensus-based rating system and framework covering the design, construction, operation, and certification of commercial facilities. LEED ratings are recognized and endorsed by the USGBC and the CaGBC as the standard for environmental/green construction and building operations and management.

Systems

Refuel’s unique closed–loop filtration systems are designed to be compatible with existing infrastructure, enhance its performance, and promote resilience and reliability in your emergency power system.

We also offer emergency mobile filtration services and portable filtration services for smaller installations and temporary filtrations solutions.

Refuel’s Filtration systesm are compatible and are designed and certified to work with:

- Low Sulphur and Ultra Low Sulphur Diesel

- Bio-Diesel

- Gasoline with up to an E-85 Ethanol rating

- Glycol

- Hydraulic oils

- Lubricating oils

Refuel Systems’ manufacturing facility adheres to ISO 9001:2008 quality control standards and use unionized trades people. All models are built using stainless steel filter housings, NEMA rated enclosures, and ULC listed and CSA certified components.